WHO WE ARE

A Leading Industrial &

Manufacturing

Company

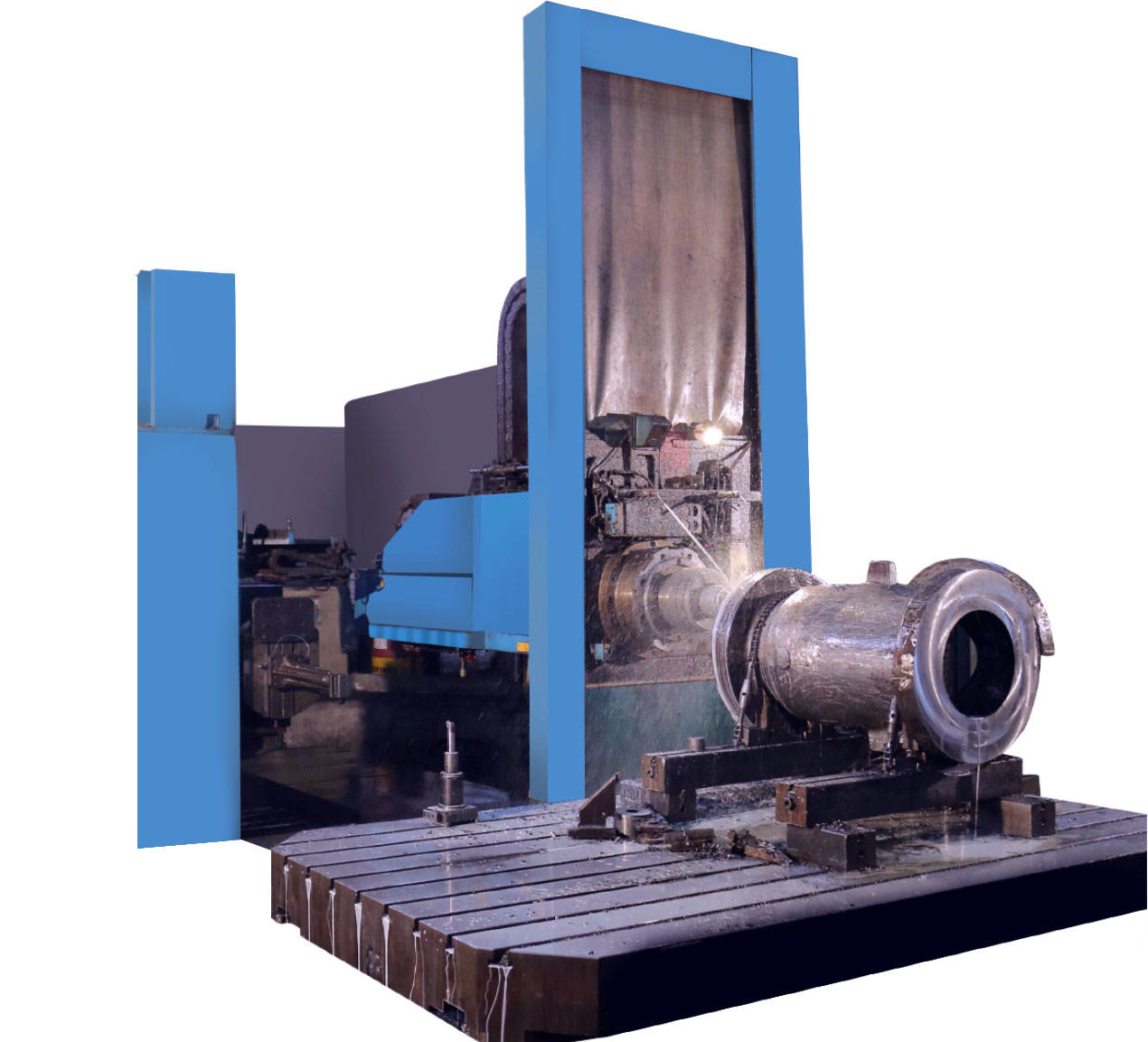

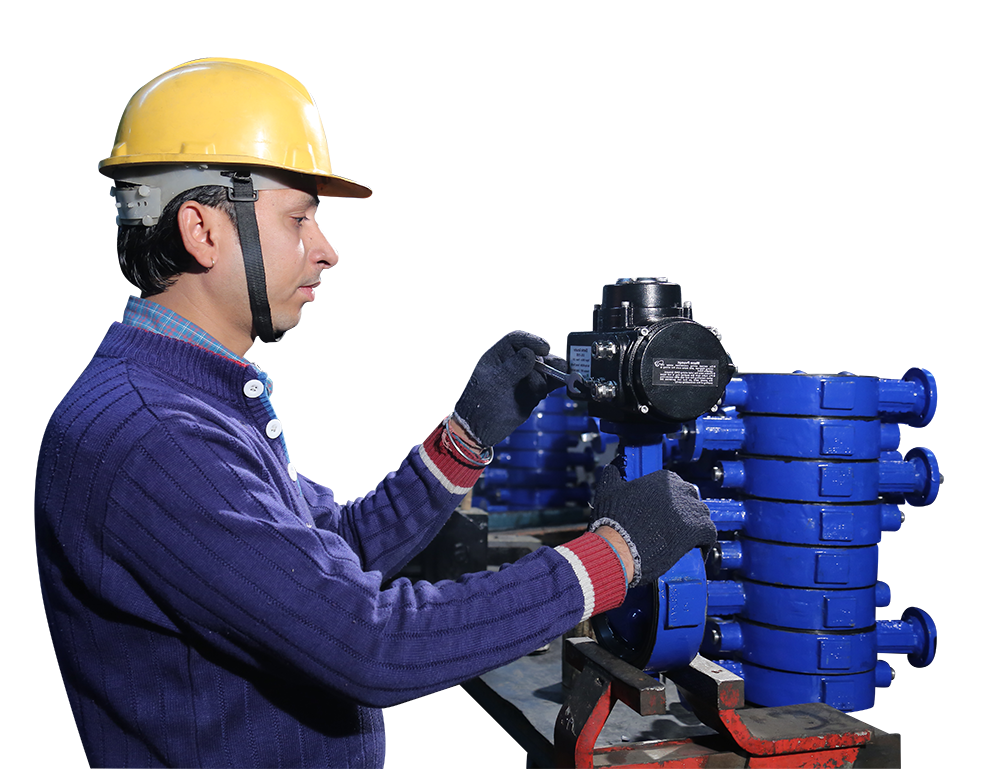

Leader Valves Limited is a leading valve manufacturing company of India. We are a totally integrated valves manufacturing unit. The company was set- up seven decades ago when India was on the threshold of industrial revolution and there were no good valve manufacturers in the country. It has over the years built up an excellent track record by following the policy of customer satisfaction through continual improvement in Designs, Manufacturing Processes and Marketing Products that are highly Competitive, Safe and Harmless to the Environment.