- Item Code: CI038A

- Disc: SS (CF8)

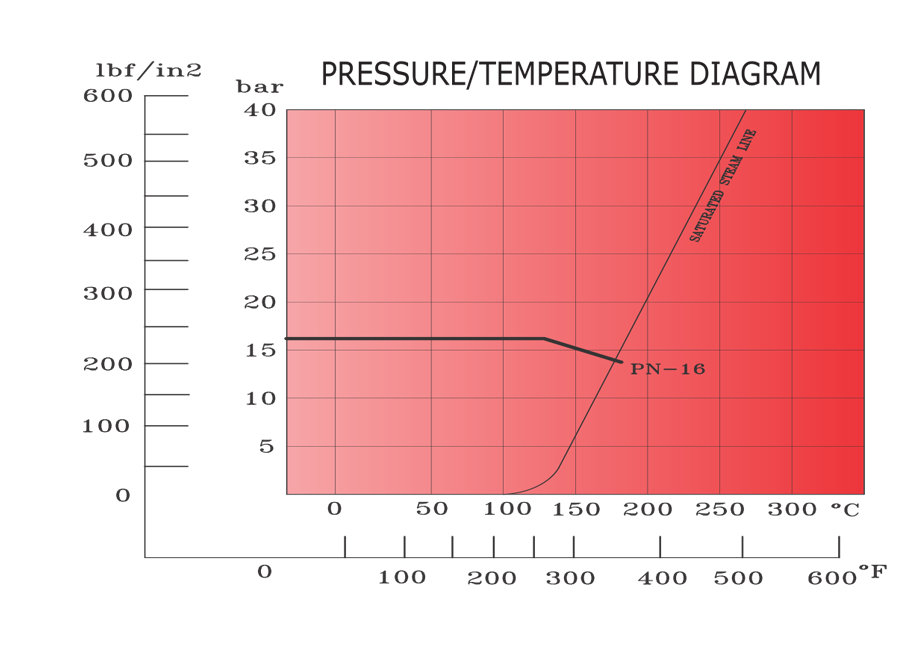

- Pressure Rating: PN-1.6

- Testing Standard: Mfg. Standard

- Size Range: 40mm to 300mm

- Product Standard: Mfg. Standard

Suitable For

Material Specification

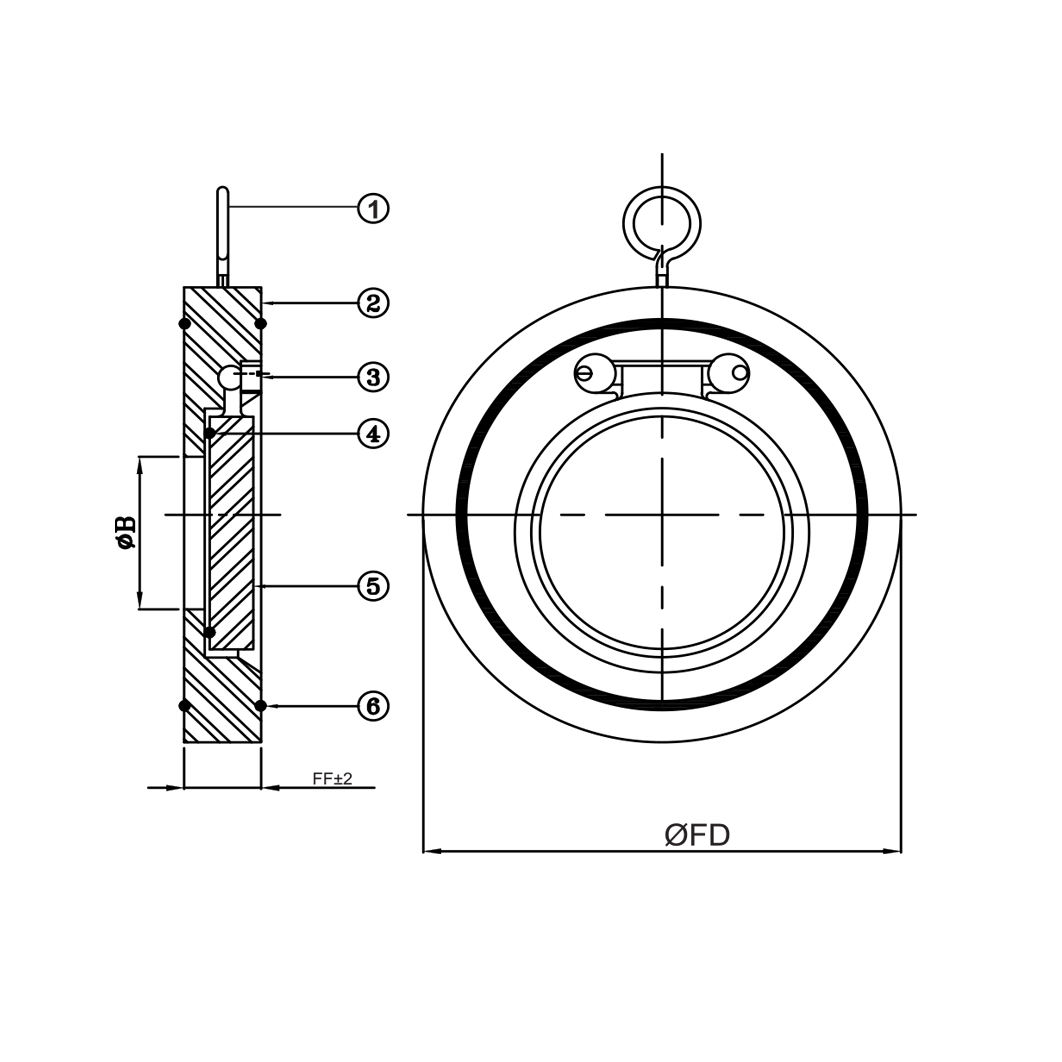

| P. NO. | NAME OF PART | MATERIAL | SPECIFICATION |

|---|---|---|---|

| 1 | HOCK | STEEL | - |

| 2 | BODY | CAST IRON | BS EN 1561 Gr. GJL 200 |

| 3 | SCREW | CARBON STEEL | - |

| 4 | O-RING | MILD STEEL | - |

| 5 | DISC | STAINLESS STEEL | ASTM A351 Gr. CF8 |

| 6 | O-RING | NITRILE RUBBER | - |

Dimensional Data

| SIZE (mm) | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

|---|---|---|---|---|---|---|---|---|---|---|

| FF±2 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 28 | 28 | 52 |

| ∅FD | 86 | 97 | 110 | 129 | 161 | 194 | 216 | 273 | 335 | 379 |

| ∅B | 24.2 | 30.7 | 41.5 | 51.7 | 70.8 | 98.5 | 118.7 | 157.3 | 195 | 228 |

Principle Features

INTRODUCTION

Leader Wafer Check Valves are designed to prevent the reversal of flow in a piping system. Valve is activated by the flowing material in the pipeline. The pressure of the fluid passing through the system opens the valve, while any reversal of flow will close the valve. Closure is accomplished by the weight of the check mechanism, by back pressure. The eccentrically mounted hinge pin in combination with the disc seat guarantees a positive shut-off of the returning media.

- Wafer Type Single Disc design.

- Renewable resilient (EPDM / Nitrile) seats ensure Leakage Class IV (Zero Leakage).

- Very low face-to-face dimensions hence space required for mounting is less than 10% of that conventional Swing Check valves.

- Short wafer body enables mounting the valve with shorter length fasteners of lesser number compared to flanged swing check valve. Approximately 50% saving in cost of fasteners.

- Tightening torque to be applied on the companion flange bolting is lower due to face sealing O-ring.

- Practically maintenance-free due to fewer number of parts and simple construction.

- Renewable resilient seat ensure Zero leakage.

- Suitable for insertion between flanges as per BS-10 table.

- Less wear and tear of seat surface due to O-Ring type body seat facing.

- The need for flange gaskets during installation is totally eliminated due to the in-built face sealing ‘0’ rings provided on the sealing face.

- Either vertically (only upwards) or horizontally installed.

END CONNECTION

- Suitable for insertion between flanges as per BS 10 Table E.

- Suitability for insertion between other flange standards also available upon request.

UTILISATION & SERVICE

- "LEADER" Cast Iron Wafer Type Check valves are suitable for above-ground installation.

- Best suited for water, heating air conditioning, and compressed air devices.

WORKING PRESSURE

- Maximum Working Pressure: 16 Bar.

- See Pressure / Temperature Diagram.

TEMPERATURE LIMITS

- Maximum Working Temperature: 45°C.

- See Pressure / Temperature Diagram.

TEST PRESSURE (Hydrostatic)

| Rating | PN-16 |

|---|---|

| Body (Hyd.) | 24 Bar |

| Seat (Hyd.) | 17.6 Bar |