- Item Code: DI0084

- Pressure Rating: PN-25

- Testing Standard: API 598

- Size Range: 50mm to 300mm

- Product Standard: API 594

Suitable For

Material Specification

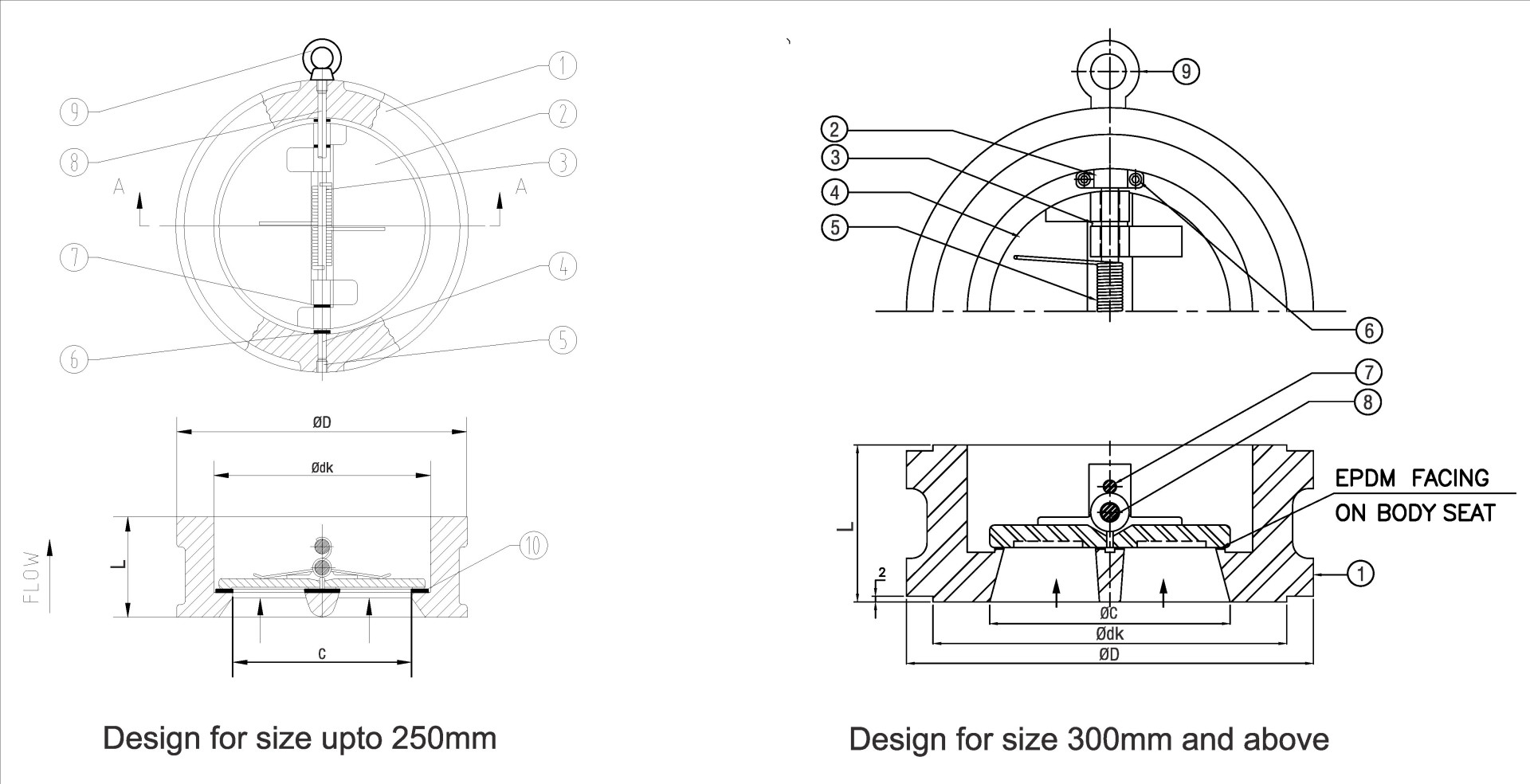

FOR SIZE UPTO 250mm

| P. NO. | NAME OF PART | MATERIAL |

|---|---|---|

| 1 | BODY | D.I. (ASTM A395) |

| 2 | DISC | CSS (ASTM A351 GR. CF8) |

| 3 | SPRING | STAINLESS STEEL 316 |

| 4 | DISC HOLDER PIN | SS 416 |

| 5 | PLUG | CARBON STEEL |

| 6 | BODY BEARING | PTFE |

| 7 | SPRING BEARING | PTFE |

| 8 | STOP PIN | SS 416 |

| 9 | EYE BOLT (DN 150-250) | CARBON STEEL |

| 10 | BODY SEAT | EPDM |

FOR SIZE 300mm AND ABOVE

| P. NO. | NAME OF PART | MATERIAL |

|---|---|---|

| 1 | BODY | D.I. (ASTM A395) |

| 2 | DISC HOLDING PLATE | CCS (ASTM A216 GR. WCB) |

| 3 | BUSH | SS (ASTM A276 TYPE 304) |

| 4 | DISC | CSS (ASTM A351 GR. CF8) |

| 5 | SPRING | SS TYPE 316 |

| 6 | L-KEY BOLT | SS TYPE 316 |

| 7 | STOPPER PIN | SS (ASTM A276 TYPE 410) |

| 8 | DISC HOLDER PLATE | SS (ASTM A276 TYPE 410) |

| 9 | EYE BOLT | CARBON STEEL (IS 2062) |

Dimensional Data

| SIZE (mm) | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

|---|---|---|---|---|---|---|---|---|---|

| L | 54 | 54 | 65 | 64 | 71 | 76 | 92 | 114 | 181 |

| ∅C | 42 | 57 | 68 | 84 | 114 | 133 | 181 | 215 | 300 |

| ∅D | 107 | 127 | 142 | 162 | 192 | 218 | 273 | 328 | 403.5 |

| ∅dk | 67 | 82 | 96 | 119 | 147 | 172 | 226 | 267 | 381 |

Principle Features

INTRODUCTION

Leader Ductile Dual Plate Check Valves are automatic, quick-acting valve designed to prevent the reversal of flow in a piping system. The two valve discs, eccentrically embedded, have springs which force the valve to close in case no pressure is available. The pressure of the fluid passing through the system opens the valve discs, while any reversal of flow will close the valve discs. Closure is accomplished by the spring action and by back pressure.

- Design Standard: API 594.

- Retainer-less Construction ensures that they do not drill entirely into the valve body to allow the hinge pin and the stop pin to be fitted with a dual-plate check valve. The feature ensures high integrity & tamper-proof design, ensures no leakage from the body.

- Body & Disc castings made of superior Ductile Iron ASTM A395 grade to ensure additional strength.

- Wafer type design, to take lesser space than the Reflux / Swing Check Valve.

- Being light in weight has more rugged construction than the standard Swing Type Check Valve, which needs expensive foundation and special supports.

- Less wear and tear of seat surface due to resilient integrally moulded body seating face.

- Stopper pin prevents the discs from coming into contact with each other and thus prevents disc damage. The stopper pin also prevents spring failure by ensuring that the discs don’t travel beyond the full-open position.

- Low cracking pressure design (operable at low pressures).

- Independent spring design feature also available which gives less scrubbing of disc & independents movement of discs.

- Inherently non-slamming, no external devices/attachment required.

- Water hammering effect is minimized in this design since the closing of valve does not depend upon any back pressure or flow.

- Either vertically (only upwards) or horizontally installed.

- Lifting eyebolt option is provided.

END CONNECTION

- Wafer type Suitable for clamping between flanges as per BSEN 1092 PN-25.

- Suitability for insertion between other flange standards also available upon request.

UTILISATION & SERVICE

- Best suited for water, HVAC, fire-fighting, compressed air applications.

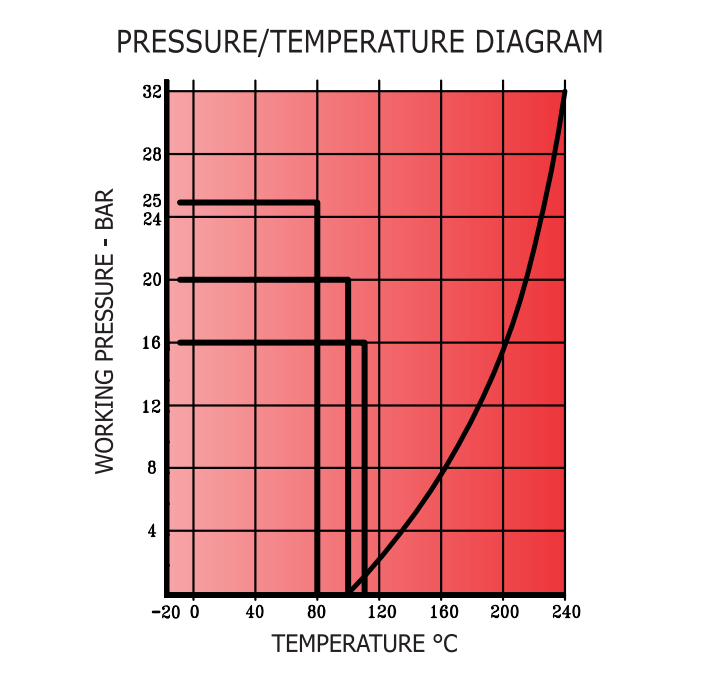

WORKING PRESSURE & TEMPERATURE LIMITS

- Maximum Working Pressure: 25 Bar.

- Maximum Working Temperature: 120°C.

- See Pressure / Temperature Diagram.

TEST PRESSURE (Hydrostatic)

| Rating | PN-25 |

|---|---|

| Body (Hyd.) | 37.5 Bar |

| Seat (Hyd.) | 27.5 Bar |