- Item Code: FCS016

- Bore Type: Full Bore

- Pressure Rating: CL-800

- Testing Standard: API-598, BSEN 12266 Part-1

- Size Range: 15mm to 50mm

- Product Standard: BSEN ISO 17292

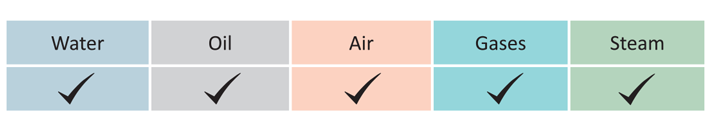

Suitable For

Material Specification

| P. No. | NAME OF PART | MATERIAL | SPECIFICATION |

|---|---|---|---|

| 1 | BODY | FORGED STEEL | ASTM A105 (*) |

| 2 | FORGED STEEL | ASTM A105 (*) | |

| 3 | BALL | STAINLESS STEEL | ASTM A276 TYPE 304 / ASTM Gr.CF8 |

| 4 | SEAT | PTFE/RPTFE | |

| 5 | BODY SEAL | PTFE/RPTFE/GRAFOIL | |

| 6 | STEM & GLAND SEAL | PTFE / GRAFOIL | |

| 7 | GLAND | STAINLESS STEEL | ASTM A276 TYPE 304 |

| 8 | BELLEVILLE WASHER | SPRING STEEL | ZINC PLATED |

| 9 | STEM NUT | STAINLESS STEEL | ASTM A276 TYPE 304 |

| 10 | STOPPER PLATE | CARBON STEEL | IS 2062 |

| 11 | LEVER (ZINC PLATED) | CARBON STEEL PLATE WITH PLASTIC SLEEVE | |

| 12 | LEVER NUT | STAINLESS STEEL | ASTM A276 TYPE 304 |

| 13 | STEM | STAINLESS STEEL | ASTM A276 TYPE 304 |

| 14 | LOCKING WASHER | CARBON STEEL | IS 2062 |

| 15 | BOLTS | ALLOY STEEL | IS 1367 CL-10.9 |

| 16 | NUTS | H.T. STEEL | IS 1367 CL-10.9 |

| 17 | ANTISTATIC BALL | STAINLESS STEEL | SS TYPE 316 |

| 18 | SPRING | STAINLESS STEEL | SS TYPE 316 |

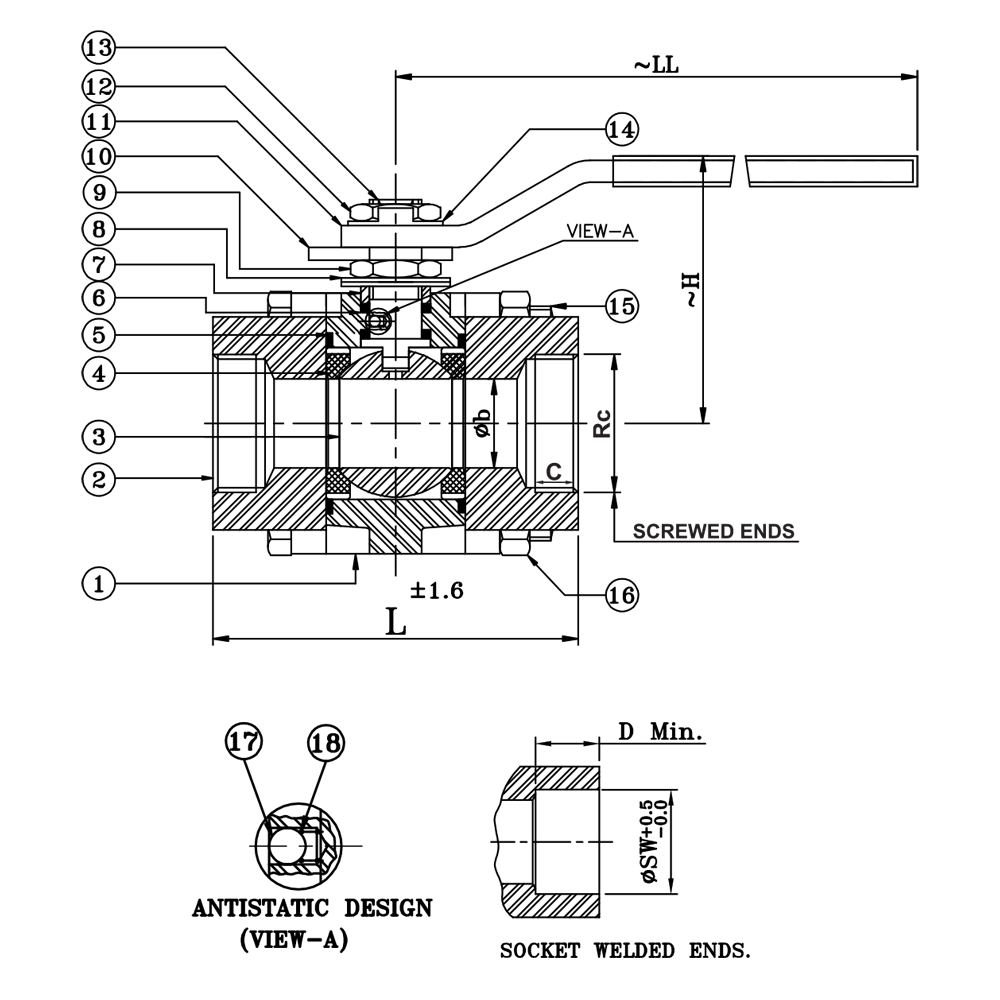

Dimensional Data

| SIZE (mm) | 15 | 20 | 25 | 32 | 40 | 50 |

|---|---|---|---|---|---|---|

| L | 60 | 70 | 85 | 95 | 110 | 120 |

| ∅b | 9.5 | 12.5 | 19 | 25 | 32 | 40 |

| ~H | 80 | 82 | 103 | 112 | 118 | 122 |

| C | 14.5 | 18 | 18 | 20 | 20 | 20 |

| Rc | 1/2" | 3/4" | 1" | 1-1/4" | 1-1/2" | 2" |

| ~LL | 165 | 165 | 180 | 180 | 230 | 272 |

| ∅SW | 21.7 | 27 | 33.8 | 42.5 | 48.6 | 61.6 |

| D | 10 | 13 | 13 | 13 | 13 | 16 |

Principle Features

INTRODUCTION

Leader Ball Valves are available in three-piece construction. It offers full flow with minimum turbulence and can balance or throttle fluids. Ball move from closed to full open in a quarter of a turn of the shaft and therefore referred to as quarter turn ball valve.

- Design Std.: BSEN ISO 17292.

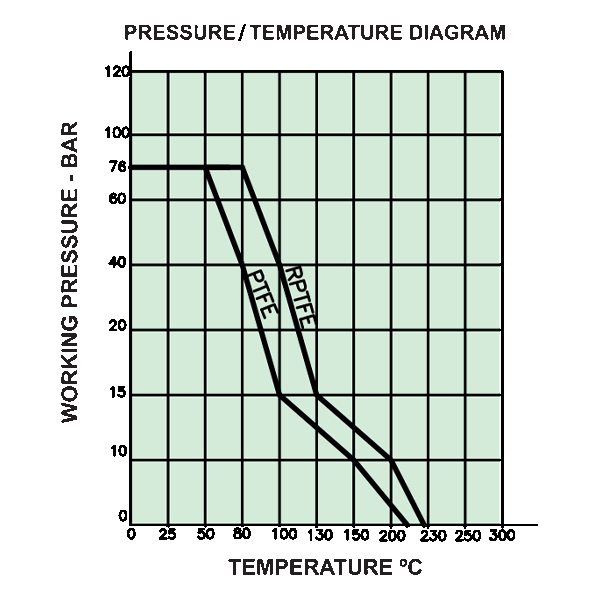

- Pressure Temperature Rating as per ISO 5208 / API 598.

- Sturdy design for high-pressure & temperature service.

- Three-piece constructions designed for easy online service.

- Floating Ball, line pressure forces the floating ball against the downstream seat to effect bubble-tight sealing.

- Mirror-finished Solid Stainless Steel Ball ensures bubble-tight sealing and lower operating torques.

- Premium quality RPTFE seats to resist high temperatures than ordinary virgin PTFE.

- Inbuilt antistatic mechanisms to provide electrical continuity.

- Blowout-proof stem design.

- Fire-safe design as per API 607, features secondary metal seats act in the event of a fire, after the soft seat totally deforms, the ball moves and touches the metal seat to form a leak-tight seal.

- Screwed Female Taper ends as per ASME B1.20.1 (NPT) / BS 21, Screwed Female Parallel ends as per ISO 228 / BS 21 available on request.

- Socket-weld / Butt Welded are available on request with 100mm Nipple on both the ends.

- Lever operated.

- Valves can be offered with electrical and Pneumatic actuators on request.

- Valves are available with IBR certification.

TEST PRESSURE(Hydrostatic)

| Rating | CL-800 |

|---|---|

| Body (Hyd.) | 207 Bar |

| Seat (Hyd.) | 76 Bar |

| Seat (Air) | 6.9 Bar |

END CONNECTION

- Screwed ends / Socket Weld.

WORKING PRESSURE

- Maximum working pressure 69 Bar @ 38°C.

TEMPERATURE LIMITS

- Maximum working temperature 175°C.