- Item Code: FCS035

- Pressure Rating: CL-150

- Testing Standard: BS 5352

- Size Range: 15mm to 50mm

- Product Standard: BS 5352, BSEN ISO 15761

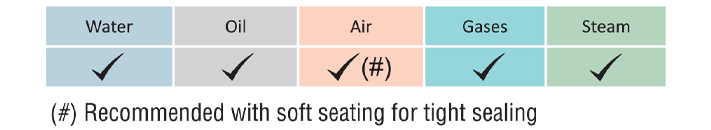

Suitable For

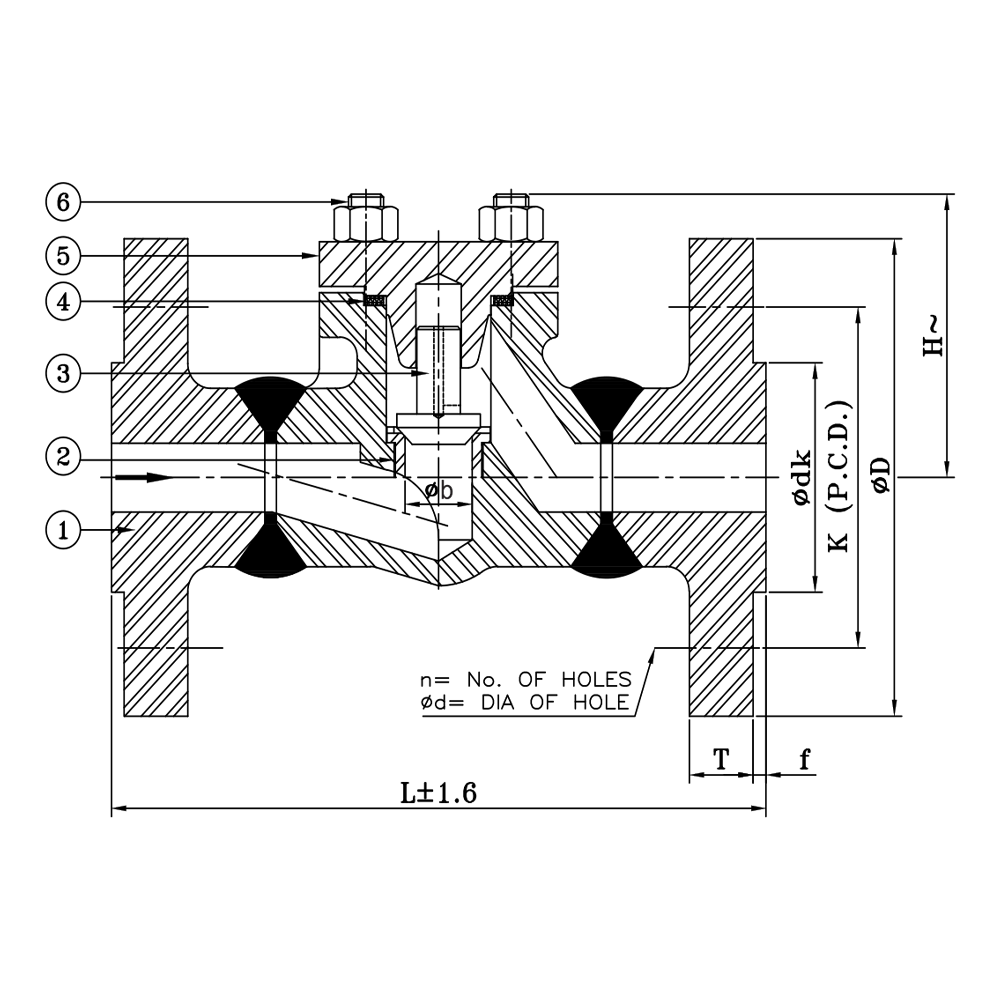

Material Specification

| P. No. | NAME OF PART | CARBON STEEL | ALLOY STEEL | STAINLESS STEEL | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | BODY | A105 | A350 LF2 | A182 F5 | A182 F11 | A182 F22 | A182 F9 | A182 F304 | A182 F316 | A182 F304L | A182 F316L |

| 2 | SEAT RING | ASTM A276 TYPE 410 | SS 304 | SS 410 | SS 410 | SS 410 | SS 410 | SS 304 | SS 316 | SS 304L | SS 316L |

| 3 | DISC | ASTM A217 Gr. CA15/ ASTIM 276 TYPE 410 |

SS 304 | CA15/ SS410 |

CA15/ SS410 |

CA15/ SS410 |

CA15/ SS410 |

SS 304 | SS 316 | SS 304L | SS 316L |

| 4 | GASKET | SPIRAL WOUND STAINLESS STEEL GRAPHOIL FILLER | |||||||||

| 5 | COVER | A105 | A350 LF2 | A182 F5 | A182 F11 | A182 F22 | A182 F9 | A182 F304 | A182 F316 | A182 F304L | A182 F316L |

| 6 | STUDS | A193 B7 | A320 L7 | A193 B7 | A193 B7 | A193 B16 | A193 B16 | A193 B8 | A193 B8 | A193 B8 | A193 B8 |

Dimensional Data

| SIZE (mm) | 15 | 20 | 25 | 32 | 40 | 50 |

|---|---|---|---|---|---|---|

| L | 108 | 117 | 127 | 140 | 165 | 203 |

| ∅b | 10 | 12.7 | 18 | 23 | 30 | 37 |

| H~ | 54 | 58 | 75 | 77 | 92 | 126 |

| ∅D | 89 | 99 | 108 | 117 | 127 | 152 |

| T | 7.9 | 8.6 | 9.7 | 11.2 | 12.7 | 14.2 |

| ∅dk | 35.1 | 42.9 | 50.8 | 63.5 | 73 | 91.9 |

| f | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| K | 60.5 | 69.8 | 79.2 | 88.9 | 98.6 | 120.6 |

| n | 4 | 4 | 4 | 4 | 4 | 4 |

| ∅d | 15.8 | 15.8 | 15.8 | 15.8 | 15.8 | 19.1 |

Principle Features

INTRODUCTION

Leader forged steel check valve is to provide with single disc. With the force of medium, the disc will automatically open or close. When the media stops the flow, the disc will be closed under its own force. No manual intervention is involved in the whole process Check valve is mainly to prevent the media reverse flow and ensure one-way flow of media channels only. It prevents accidents while a sudden loss of power in the pipeline medium such as the power equipment like pump damages, and the medium reserve flow against power source.

- Design Std.: BS 5352, BSEN ISO 15761.

- Pressure Temperature Rating as per ASME B16.34, BSEN ISO 15761.

- Sturdy design for high-pressure & temperature service.

- Bolted body-cover design, Valves with welded cover also available on request.

- Bolted body-cover joints provided with spiral-wound stainless steel gasket and graphite filler for protection against leaks.

- Piston/Disc is guided in the Cover assuring accurate return to seating to achieve leak tightness.

- Spring-loaded disc on check valves suitable for non-horizontal applications too available on request.

- Minimum differential pressure of 1 bar required for operating the valve.

- Flanged ends as per ASME B16.5 Raised Face.

- Spring-loaded disc on check valves available for non-horizontal applications.

- Low-Temperature Carbon Steel & Austenitic SS forging for body and cover design qualified as per BS 6364 for Cryogenic service available on request.

- Valves can be offered to NACE MR-0175 and other special NACE requirements.

- Valves are available with IBR certification.

TEST PRESSURE(Hydrostatic)

| Rating | CL-150 |

|---|---|

| Body (Hyd.) | 30 Bar |

| Seat (Hyd.) | 22 Bar |

END CONNECTION

- Welded on flanges as per ASME B16.5 Raced Face.

WORKING PRESSURE

- Maximum working pressure 20 Bar (CL-150).

TEMPERATURE LIMITS

- Maximum working temperature 425°C.

TRIM MATERIAL COMBINATION (ON REQUEST)

| Trim No. | Seat Ring Face | Wedge Seat Face | Stem | Backseat Bush | Lantern Ring |

|---|---|---|---|---|---|

| 2 | F304 | F304 | F304/AISI304 | F304/AISI304 | F304/AISI304 |

| 5 | STELLITE(#6) | STELLITE(#6) | F6a/AISI410 | F6a/AISI410 | F6a/AISI410 |

| 8 | STELLITE(#6) | F6a/13%Cr. | F6a/AISI410 | F6a/AISI410 | F6a/AISI410 |

| 9 | MONEL | MONEL | MONEL | MONEL | MONEL |

| 10 | F316 | F316 | F316/AISI316 | F316/AISI316 | F316/AISI316 |

| 12 | 316+Stellite(#6) | 316 | F316/AISI316 | F316/AISI316 | F316/AISI316 |

| 13 | ALLOY 20 | ALLOY 20 | ALLOY 20 | ALLOY 20 | ALLOY 20 |