- Item Code: CI0016

- Pressure Rating: PN-16

- Testing Standard: BSEN 12266 Part-1

- Size Range: 15mm to 250mm

- Product Standard: BS 5152, BSEN 13789

Suitable For

Material Specification

| P. NO. | NAME OF PART | MATERIAL | SPECIFICATION |

|---|---|---|---|

| 1 | BODY | CAST IRON | IS 210 Gr.FG 200 |

| 2 | BODY SEAT RING | F.S.S. | ASTM A182 Gr. F6a |

| 3 | DISC | 13% Cr. Steel | CA15 / F6a |

| 4 | LOCKING WASHER | STAINLESS STEEL | TYPE 410 |

| 5 | DISC NUT | STAINLESS STEEL | TYPE 410 |

| 6 | STEM | STAINLESS STEEL | TYPE 410 |

| 7 | GASKET | C.N.A.F. | |

| 8 | PACKING | FLEXIBLE GRAPHITE | |

| 9 | GLAND FLANGE | CAST IRON | IS 210 Gr.FG 200 |

| 10 | BONNET | CAST IRON | IS 210 Gr.FG 200 |

| 11 | YOKE BUSH | GUN METAL | LTB2 |

| 12 | LOCKING SCREW | STAINLESS STEEL | TYPE 316 |

| 13 | THRUST PLATE | STAINLESS STEEL | TYPE 410 |

| 14 | STUDS & NUTS | CARBON STEEL | IS 1363 |

| 15 | T-HEAD BOLTS & NUTS | CARBON STEEL | IS 1363 |

| 16 | HAND WHEEL | CAST IRON | IS 210 Gr. FG 200 |

| 17 | WASHER | STAINLESS STEEL | TYPE 410 |

| 18 | NUT FOR HAND WHEEL | CARBON STEEL | BS 916 |

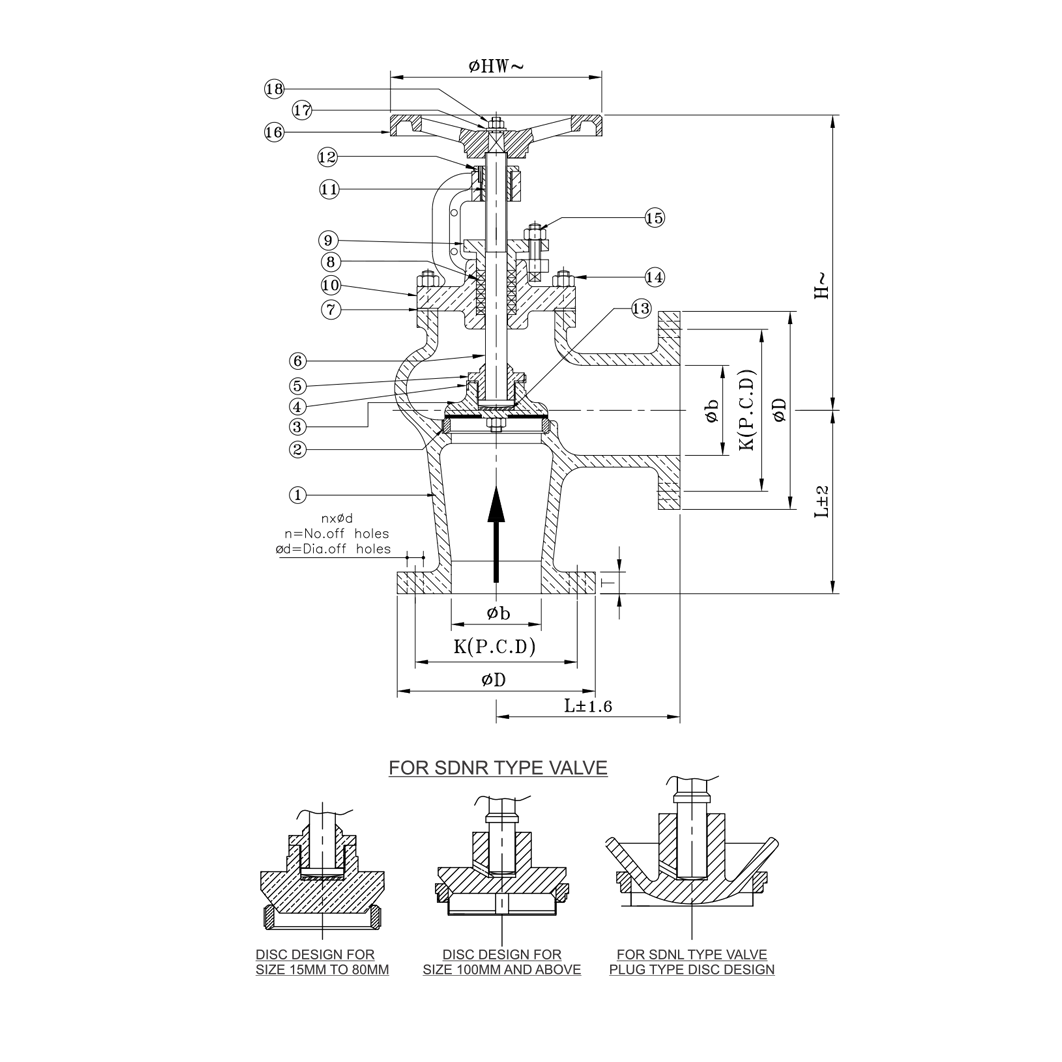

Dimensional Data

| SIZE (mm) | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L±2 | 80 | 95 | 100 | 105 | 115 | 125 | 145 | 155 | 175 | 200 | 225 | 275 | 325 |

| ∅b | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 |

| H~ | 145 | 145 | 145 | 175 | 190 | 225 | 250 | 280 | 330 | 365 | 412 | 418 | 575 |

| HW∅~ | 120 | 120 | 120 | 120 | 140 | 140 | 180 | 180 | 235 | 260 | 320 | 400 | 400 |

| ∅D | 95 | 105 | 115 | 140 | 150 | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 395 |

| T | 14 | 16 | 16 | 18 | 18 | 20 | 20 | 22 | 24 | 26 | 26 | 26 | 28 |

| K | 65 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 |

| n | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 8 | 8 | 8 | 8 | 8 | 12 |

| ∅d | 14 | 14 | 14 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 23 | 23 | 23 |

Principle Features

INTRODUCTION

Leader Cast Iron Globe Valves (Angle Pattern) are designed to stop, start and regulate flow. The ends of this Globe valve are at an angle of 90 degrees, and fluid flow occurs with a single 90 degrees turn. They are recommended to be used in applications that have periods of pulsating flow because of their capability to handle the slugging effect of this type of flow.

- Design Std.: BSEN 13789.

- Angle pattern, O/S & Yoke Type, Rising Stem.

- Metal to Metal seating.

- Stainless Steel Body & Disc rings, Stainless Steel Stem.

- Composition disk uses a hard, non-metallic insert ring on the disk, which ensures a tighter closure.

- Additional advantage of an angle valve is that it provides a 90° turn in piping so fewer joints are required and make-up time and labour are reduced.

- Flanged ends as per DIN 2533 PN16 (RF).

- Compact & rigid structure.

- Used in applications that have periods of pulsating flow because of their capability to handle the slugging effect of this type of flow.

- Small opening and closing torque.

- The outside screw & Yoke configuration protects the stem & offer quick visual indicator of open/closed position.

- Using Grafoil packing, reliable sealing, light and flexible operation.

- Robust construction of hand wheel in open spoke design.

- Provision for re-packing under pressure in the installed condition.

- Easy visual control of open/closed position marked on the hand wheel.

- Operation mode manual, gear, electric.

- Available with open-shut indicator & locking arrangement on request.

- Valves are available with IBR Certification up to size 150mm.

- Widely used for utility services such as water supply, power plants, gas supply, district heating piping, irrigation projects, air conditioning systems, as well as food processing industry, Boiler industry, pharmaceutical, and powder industry for throttling service.

END CONNECTION

- Flanged as per DIN 2533, PN-16 (RF).

- Flange drilling as per other standards also available upon request.

UTILISATION & SERVICE

- Best suited for potable water, treated fresh water, neutral liquids Steam & some gases.

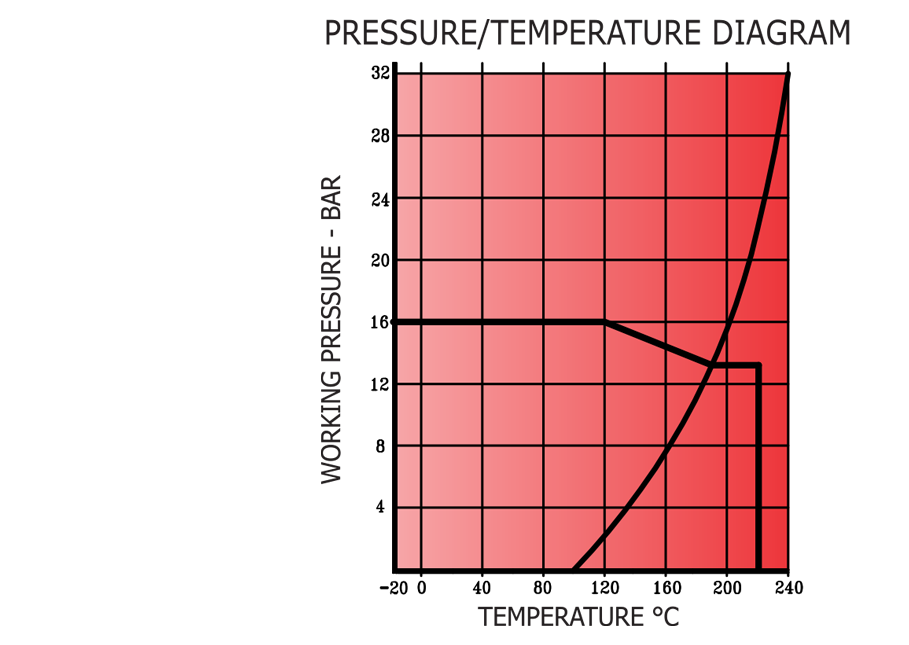

WORKING PRESSURE

- Maximum Working Pressure: 16 Bar.

- See Pressure / Temperature Diagram.

TEMPERATURE LIMITS

- Maximum Working Temperature: 220°C.

- See Pressure / Temperature Diagram.

TEST PRESSURE (Hydrostatic)

| Rating | PN-16 |

|---|---|

| Body (Hyd.) | 24 Bar |

| Seat (Hyd.) | 16 Bar |